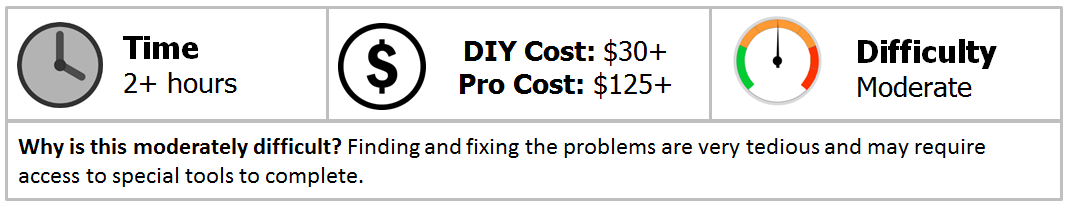

Audi A4 B7: Suspension Noise Diagnostic

Suspension problems can seem daunting, and it can be hard to pinpoint exactly which part is making the noise. Fortunately, fixing the problem may not be as hard as you think, and we'll help you find it.

This article applies to the Audi A4 B7 (2005-2009).

Diagnosing suspension noise can sometimes be a literal headache, and pinpointing it can be really tough. Frankly, there are lots of parts that all work together to provide a quiet, comfortable ride, and precise handling, so when a problem arises, noise can come from more than just the problematic part. First you have to narrow down the location of the loudest noise, then you have to figure out what component is responsible. Fortunately, certain parts are attributed to creating certain types of noises over the years, and have been reported and cataloged in the forums. For example, CV joints tend to click when they fail, while bushings may squeak, and control arms go clunk. We've listed some common issues that can cause suspension noise on you Audi A4, and what types of noise, in the article below.

Materials Needed

- Ratchet set

- Torx driver set

- Special tools according to repair (each tool is listed in their sections)

- Jack

- Jack stand

- Flashlight

Step 1 – Check your axles

The CV joints might be dry.

Power is transferred to the wheels via the drive axles, comprised of a half shaft and two constant velocity (CV) joints found on either end. The problems usually don't stem from the shaft themselves, unless the vehicle was in a serious accident causing one to get bent, but instead from the joints. These CV joints are encased in a thick rubber boot that keep the bearings supplied with grease in order to keep them rotating smoothly. Over time, these boots can tear and leak, causing the bearings to lose lubrication, and allowing dirt and water to get into them, which makes them ultimately fail. When they do dry up, you'll hear a loud clicking noise that varies with road speed, and gets loader when you go around corners. To inspect your axles, complete the following:

- Loosen the lug nuts.

- Safely jack up and secure your vehicle.

- Remove the suspect wheel.

- Take your flashlight and peer under the vehicle.

- Locate each boot and check for tears or leaks.

- Squeeze the boots by hand and see if any grease appears.

- With the car off the ground and in neutral, rotate the wheel and check for play and noises.

- If any appears to be damaged, replace the unit.

Replacing the drive axle requires the use of a breaker bar or impact gun, and can be tough for the home mechanic without access to a proper lift and professional tools.

Step 2 – Check your control arms

The bushings may have failed.

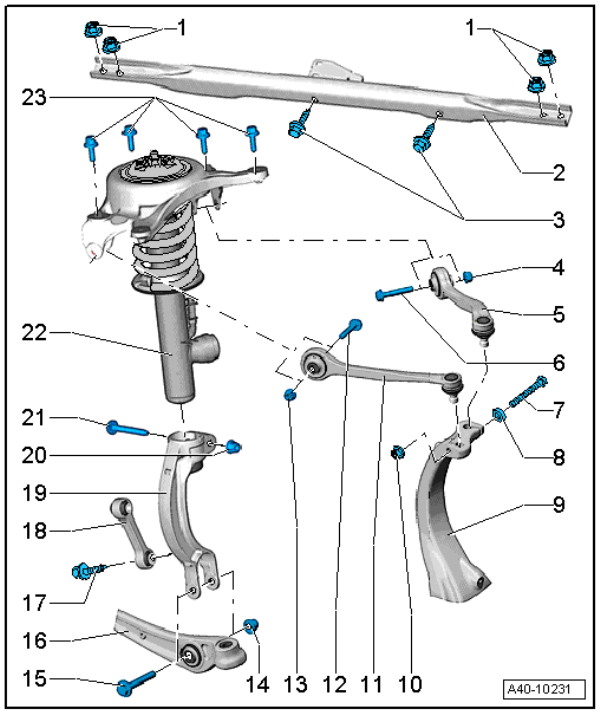

The Audi A4 B7 upper control arms have a multi-link design, with four individual control arms per side, each one with a bushing and a ball joint that can fail and cause noises. When these parts fail, you can hear a very distinct creaking noise come from the upper portion of the wheel well. Sometimes they have been known to produce a clunk when going over bumps as well. A good way to check them is to do the following:

- With the car on the ground, locate the control arm where the noise is most noticeable.

- Grab the control arm by hand and check for any free play.

- Ask someone to push the car up and down while you watch and listen to the suspension.

- Listen for any creaks or clunks.

Replacing the control arm requires using a special tool called a ball joint puller, which is available in several different forms, and can often be borrowed from chain auto parts stores. You will also need lubricant to remove any seized bolts. The whole process is detailed in the article here: How to Replace Ball Joints/Control Arms.

Step 3 – Check your shocks

They may be leaking and bad.

The shocks are full of oil that passes through small openings inside, damping the suspension motions, and when they fail, something called bottoming out occurs. Without the damping effect, the wheels can bounce more over bumps and slam into the rubber bump stops, which means the entire chassis of the car will feel the impact of the road. Noises made with a damaged strut occur when the entire shock of the bump is transferred into the chassis of the car, and often sounds like someone slamming on a wooden door. Replacing the shock requires the use of a spring compressor and ball joint puller. You can check to see if the shocks are leaking by securing the car in air, removing the wheel and visually inspecting it. An old test of the effectiveness of a shock is to push down on the corner of the car and see how quickly it settles after bouncing back; immediately is the proper time frame for a German sports sedan like an Audi.