Audi A4 B7: Suspension Performance Diagnostic Guide

Locating that mysterious suspension issue can be a real headache. Fortunately, we put together a list of problems, and solutions, that can help you repair your suspension.

This article applies to the Audi A4 B7 (2005-2009).

Due to the complexity of the multi-link suspension on your A4, it can sometimes be difficult to locate a worn suspension component. Bushings, ball joints, and struts all have special symptoms that make them stand out as the main problem. Control arms, for example, will cause the steering wheel to knock every time you make a tight turn, while bad tires can cause a pull to one side, noise, or overall instability. Use the information provided here to pinpoint a suspension problem and repair it.

Materials Needed

- Ratchet set

- Torx driver set

- Jack

- Jack stand

- Flashlight

- Various other tools (see each step)

Step 1 – Check your tires

Tires might be worn or low on air.

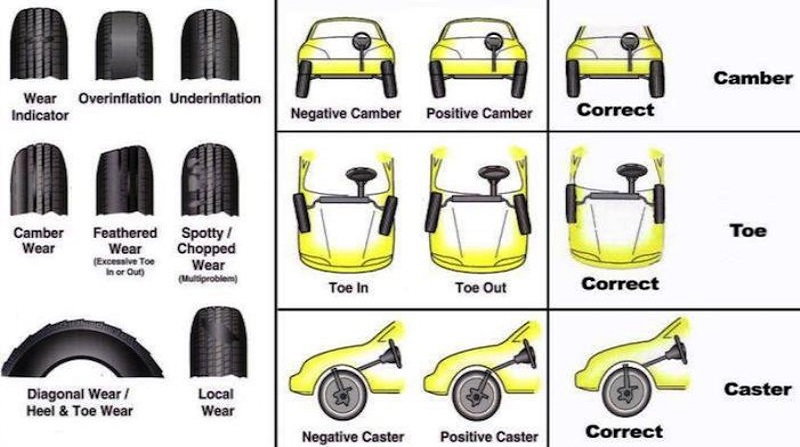

If you are experiencing any driveability issues, the first thing you should check are your tires. Tires are responsible for providing traction to your 2-ton vehicle in dry, wet and/or snowy conditions. They must be properly balanced, inflated, and installed in order to provide a satisfying driving experience. An unbalanced tire can cause the car to shake at high speeds, while worn tires will cause issues with traction and stopping power. Even something as simple as under or over-inflating a tire can make the car behave strange, and pull to one side. If you suspect one tire, try rotating them and see if the problem changes to a different corner of the car. To check your tires, go outside on a sunny day and look for the following:

- Bulges on the sidewall

- Date of the tire (If it's older than seven years, it must be replaced.)

- Tread wear must be more than 3/32"

- Exposed bead

- Flat spots

If your tires have any of these issues, replace them immediately.

Figure 1. Check your tires.

Figure 2. Read the tire date code.

Step 2 – Check your control arms

Bushing or ball joint might be bad.

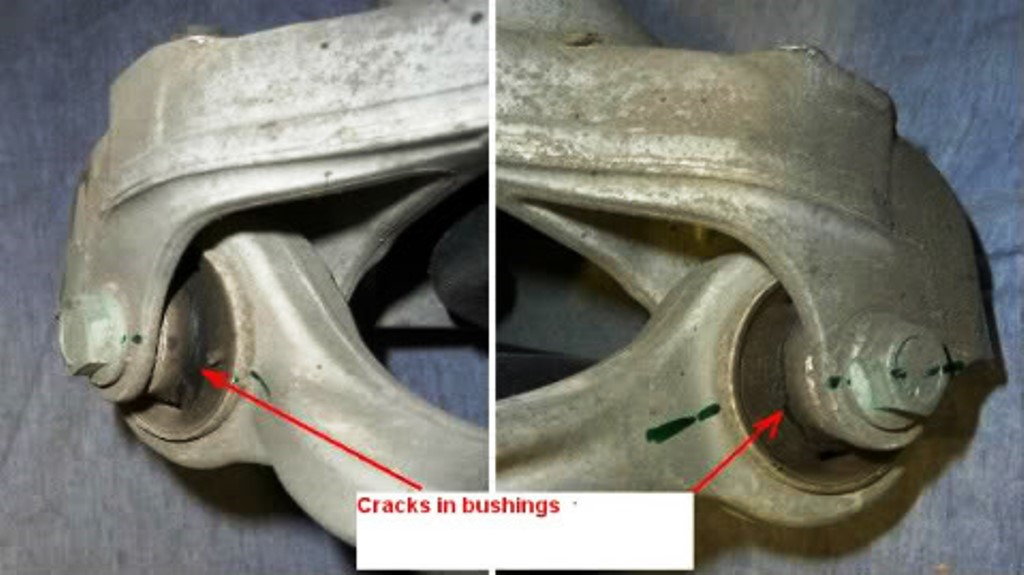

The control arms function to locate the wheel in both a vertical and horizontal axis. Each arm has a ball joint and a bushing at the end to allow a certain degree of movement, and help absorb the impact from the road before it gets to the cabin. These bushings have a limited lifespan, and will start to deteriorate, with the rubber getting hard and falling apart. When your control arm has a bad bushing or ball joint, you will start to hear a loud creaking noise, or a clunk, paired with less accurate handling. To check on the control arms and bushings:

- Jack up the car.

- Remove the front wheels.

- Pull the control arms, front and back, side to side, feeling for play.

- Examine the bushings for signs of cracked or missing rubber.

- Replacement control arm kits are easy to install, though the full kit can be expensive.

- Replacing just the bushing is possible, but more work.

Step 3 – Check your alignment

You may need one.

The alignment of your car can change with time, just through normal driving, and on top of that, every time you replace a suspension component, things can get out of adjustment. A car that is out of alignment can have a lot of issues that mimic a failing part, such as vibrations in higher speeds, wandering, pulling to one side, or severe over-steer or under-steer. If problems persist and you can't pinpoint the cause, it may just be an alignment issue. An alignment will cost $75.

Figure 4. Bad alignment is obvious in tire wear.

Figure 5. Have the professionals set everything right.

Step 4 – Check your replacement parts

Cheaper new parts may have a defect.

So what happens when you source your problem to a control arm, replace the part, and still end up with a noise? With the influx of generic lower quality replacement parts on the market, some forum members have found new parts that are already out of spec, or that go bad quickly. Buy only name brand parts from a source that can be trusted, and inspect them before installation. If you still have issues, check your recently installed suspension parts for any defects or small rips and cracks on the bushings. Replace them again if necessary.

Pro Tip

A good way to destroy brand new bushings is to tighten the bolts with the car in the air, then put it on the ground. Remember to only fully tighten the control arm bolts with the weight of the car on the tires.

Related Discussions

- Source of Front Suspension Noise/Creak - AudiWorld

- Upper Control Arm Bushing Replacement - AudiWorld

- Alignment (Was It Bad, Is It Good?) - AudiWorld